|

| |

|

File No.: Battle Relic # 29

Title: "Zimmerit"

Investigation made at: An

undisclosed location in the

Netherlands

Period Covered: 1942 - SEP

1944

Date: NOV 2011 to JAN 2017

Case Classification: Study of

a chemical component named

“Zimmerit” which in Nazi Germany was

used to create a non-magnetic layer

on armored vehicles against

magnet-borne anti –tank shape

charges. Recreation of Zimmerit and

testing its (non-)magnetic and

(in-)flammable properties.

Case Status: Case Closed

REASON FOR INVESTIGATION: In

an abundance of publications the

substance “Zimmerit” is described.

This non-magnetic anti magnetic

charge substance was only used by

Nazi Germany; not by its enemies. It

gave a very distinctive look to

their weaponry. It is this agency's

intention to learn if Zimmerit was

in fact non-magnetic and of it would

ignite. |

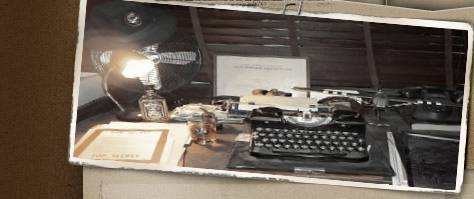

(click to enlarge)

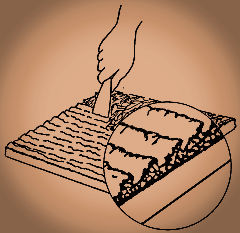

Applying recreated

Zimmerit

on an original World War Two

Nazi tank part |

SYNOPSIS:

Zimmerit was a non-magnetic coating

produced for Nazi armored fighting

vehicles during World War II for the

purpose of opposing magnetically

attached anti-tank mines, although

the Third Reich was the only country

to use magnetically attached mines

against armored vehicles in any

significant number. Zimmerit was

developed by the German company

Chemische Werke Zimmer AG. The

coating was a buffer that prevented

direct contact of magnetic mines

with metal surfaces of vehicles. It

was normally ribbed to increase

overall thickness. The magneto

static field decreases very rapidly,

with the increase of distance; the

non-magnetic coating holds the

magnet of the mine too far from the

steel of the vehicle for it to stick

to it. |

.jpg)

1926 commercial logo

of Zimmerit

corrosion protective coating |

|

Zimmerit was applied to some

tanks and casemate-style closed-top

self-propelled guns and tank

destroyers produced from DEC 1943 to

9 SEP 1944. It was only rarely

applied to open-top Armored Fighting

Vehicles. The rough appearance of

the coating gave a distinct

appearance, for one type a

"shingle-like" look to the vehicles

it coated. Application of Zimmerit

was usually done at the tank

manufacturing plant. Zimmerit was

discontinued from factory

application on 9 SEP 1944 and from

field application on 7 OCT 1944

because of concerns that projectile

impacts could ignite it. These

proved false, but the order was

never withdrawn. Applying and drying

Zimmerit added days to the

production of each vehicle, which

was unacceptable because of the

shortage of tanks in the last stage

of the war. No similar material was

used on post-war tanks as the

widespread use of man-portable HEAT

(High Explosive Anti-Tank) rockets

such as the American Bazooka and the

British PIAT (Projector Infantry

Anti-Tank) made magnetic mines

obsolete. |

|

(click to enlarge)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

Zimmerit coating on

Third Reich tanks

(Note a rare case of Zimmerit

applied on Königstiger mudguards in

the last image)

_small.jpg)

Period images of the

use of the Hafthohlladung |

|

Ingredients

Zimmerit was made up of the

following:

40% Barium Sulphate, BaSO4 - is made

from Barium (Ba) treated with

Sulpheric acid (H2SO4), and is

water-insoluble

25% Polyvinyl Acetate, PVA -

commonly known as white carpenters

glue

15% ochre pigment, An earth-toned

coloring material

10% Zinc sulphide and ZnS - a

natural mineral, and a Zinc ore.

70% Zinc Sulphide and 30% Barium

Suphate give Lithopone, a white

pigment

10% sawdust

Given the fact that Zinc Sulphide

and Barium Sulphate make up for 50%

of the ingredients of Zimmerit and

that both chemicals are used to

produce Lithopone, this agency has

decided to use Lithopone as final

product as an ingredient for 50% of

all Zimmerit to be manufactured and

not to use the precursors Sulphide

and Barium Sulphate.

|

The application of

Zimmerit on armor |

|

Two leading sources for purpose and

ingredients of Zimmerit

1)

Post-war interview with chief

engineer Robert Pertuss of the

Henschel tank manufacturing company

in Kassel, Germany.

2) British Intelligence Objectives

Sub- Committee report "Zimmerit"

Anti-Magnetic Plaster for AFVs, by

Major J.W. Thompson and Mr. C.E.

Hollis.

|

TIGER I :

50th Anniversary

Commemorative Edition

Hardcover – Illustrated,

1992

by Uwe Feist (Author,

Illustrator), Bruce Culver

(Author)

Published by Ryton

Publications, Retford Notts,

UK, 1992 |

The purpose and initial application

of Zimmerit are best described in an

interview with Herr Robert Pertuss,

chief engineer at the Henschel tank

manufacturing company in Kassel,

Germany:

"One day Herr

Kniepkamp (of Heereswaffenamt)

showed up at Kassel and reported

that the Russians had used magnetic

mines, which tank hunting teams

attached to the sides of our tanks

and could be made ineffective by a

thick grooved layer of some form of

cement applied over the surface of

our vehicles. With this method the

magnets would not get a strong

enough grip to keep the mines in

place. Our Purchasing department was

able in an afternoon to telephone

I.G Farben chemical company to find

out what materials would be

suitable, available and quickly

obtainable. It had to be fast drying

and stone hard when dry. Two days

Later the first drums of "Nitro-Spachtel"

arrived. Using improvised tools made

out of sheet metal we made a test

application. In only 3 hours the

material was dry and could be

painted. The drying time shortened

considerably when we used a blow

torch to dry the material. Tigers

ready for delivery the day after the

"Nitro-Spachtel" arrived were coated

and painted and we delivered Tigers

with the Material until the end of

production."

We found that most of the

publications on the ingredients of

Zimmerit repeat the content of one

leading publication in the JAN-APR

1983 issue of Armoured Fighting

Vehicle News Magazine.

Information from

a secret British Intelligence

Objectives Sub- Committee report:

The information is now unclassified

and entitled, "Zimmerit"

Anti-Magnetic Plaster for AFVs,

which was reported by Major J.W.

Thompson and Mr. C.E. Hollis. The

report is dated July 1945, and is

not complete due to insufficient

information, or the failure to

locate persons with detailed

knowledge of the subject. The

investigation was started with the

hope that a way might be found to

defeat magnetic mines used against

British armor in the war with Japan.

In 1943 the Germans adopted a thick

coating for the vertical armored

surfaces of their tanks. This

coating was designed to defeat the

affects of mines placed on armored

vehicles, mainly tanks, by

determined Russian infantry assault

teams. The mines were attached to

the tanks and held in place by

magnets built into the bottom of the

mines. The function of the

"Zimmerit" was simply to provide a

non-ferrous magnetic gap between the

steel armor and the magnets, in

other words a non-magnetic

stand-off. Early in 1944 samples of

Zimmerit were taken from captured

vehicles and instructions for its

use obtained from prisoners of war.

The composition of Zimmerit was

analyzed by C.S.A.R. and found to be

the following:

Polyvinyl Acetate-25%, as binder or

glue;

Wood Fiber-10%, as filler;

Barium Sulphate-40%;

Zinc Sulphide-10%;

Ochre Pigment-15%, for the dark

yellow color.

On August 14, 1945 the investigating

team visited the Henschel Werke at

Kassel, Germany and interviewed the

Director of Production and

Production Engineer. The following

information was obtained. The

Zimmerit was received in drums from

Chemische Werke Zimmer in Berlin,

but they thought production had

taken place in various centers

because of the large scale demands,

and because of factory dispersal.

The material arrived in a

consistency of soft putty (others

have compared it to paste, plaster

or plastic). It contained a volatile

solvent smelling like acetone. No

thinners were added before use as it

worked very easily even when handled

by inexperienced personnel. The

surface of the tank did not need to

be prepared before applying

Zimmerit, but it was normal to coat

the vehicle with anti-corrosive

primer. The Zimmerit was applied to

the surface in two coats, using a

sheet metal trowel. The first coat

was 5mm thick and was marked out in

squares using the edge of the

trowel. This coat was allowed to dry

at ordinary temperatures for 24

hours. The second coat was applied

thinner and marked in wavy lines

with a metal comb. The crisscross

squares increased the adhesion of

the second coat, while the comb

markings gave a camouflage finish,

plus poor contact for mines. After

the application of both coats, the

surface was treated by a gas

blow-lamp to harden it. This took

about an hour per tank and no

difficulty was experienced in

getting satisfactory hardness

without the Zimmerit becoming

brittle. (I have seen samples of

aged Zimmerit and it reminded me of

compressed sawdust.) During the

hardening process the solvent was

removed by the heat of the blow-lamp

on the surface. The chief thing to

watch was not to leave any soft

spots which could be brushed off the

vehicle if not hardened properly. If

the Zimmerit was not heated with a

blow-lamp it took eight days to

harden. This was impractical

considering the urgent need of tank

delivery to the front. The

Production Engineer of Henschel

Werke said that the company did not

help in the development of Zimmerit,

but simply applied it to vehicles.

He thought that Zimmerit was dropped

late in the war due to the

development of better anti-tank

weapons. No mention was made of how

successful Zimmerit was, however,

when the British Army captured the

Henschel Werke they removed about

100 tons of Zimmerit. The

investigating team next visited the

Karl Freudenburg A.G. in Weinheim,

Germany and talked with the

company’s Polyvinyl Acetate experts.

Again, this company had not helped

in the development of Zimmerit, but

did work on the P.I.B. mineral oil

adhesives for sticky bombs. The

Polyvinyl Acetate was used as an

emulsion in camouflage paints and as

a solvent such as Ethyl Acetate and

Toluene during the war. It was

mentioned that C.W. Zimmer of Berlin

was well known for paint manufacture

during that time, and probably used

Polyvinyl Acetate.

On visiting I.G. Farbenindustrie

A.G. Hochst, Germany, the Plastics

Development Manager and Production

Manager were interviewed. They said

that they had heard of the C.W.

Zimmer Co., but also knew nothing of

the development of Zimmerit. It was

also mentioned that such things were

kept secret. After referring to the

company’s records it was learned

that Mowilith 20 (a Polyvinyl

Acetate) was sold to the C.W. Zimmer

Co. In July 1943, but they had no

idea if the company or its personnel

still existed. The general

properties of Polyvinyl Acetate were

discussed. Mowilith 20 was 50%

benzene solution (this is what

smelled and was burned off with

blow-lamps). It had an average MW of

3500 (Staudinger viscosity method, 1

- 2% solution) and a melting range

of 40 to 50 degrees C. It was also

confirmed that the blow-lamp would

remove the solvent and adhere the

Zimmerit to the armor, thus

increasing its resistance to shock.

In regard to adhesion, it was

suggested that a clean or just

painted surface would be better than

a greasy or rusty one. Also, that

Polyvinyl Acetate with a pigment

mixture (Zimmerit had 15% ochre)

were somewhat water-resistant, but

due to thermal behavior of Polyvinyl

Acetate its use was limited in

plastics as it became brittle when

cold. In conclusion, the team

decided that the C.W. Zimmer Co. was

responsible for Zimmerit and every

effort should be made to contact

them. They also were wondering if

Zimmerit, thinned down, could have

been sprayed on vehicles to speed up

application time. However, no

follow-up research was done due to

the end of WW2. |

Battlefield myth testing

experiments

A. Magnets: Original magnet

charge magnets, normal magnets and

neodymium magnets

To test original, period Zimmerit

coats and self-made Zimmerit, we

acquired an array of magnets of

different strength and sizes. From

an online auction website we even

bought a complete set of original

magnets of a Nazi magnetic hollow

charge; or “Hafthohlladung”. On 06

OCT 2014, the seller named “Pjotr”

from Poland, answered us by e-mail

when asked where he’d found the

magnets:

"Hello! I found magnets on

defensive line of Erich Koch

gaulajter of East Prussia. The line

defended the access for 3 months to

prus eastern. Ran about 12 km to the

east of Suwałki.Magnets found in

“Nowa Wieś,, willage.On my area

fights lasted from the 1944r summer

to the 1945r winter. The Area very

much is permeated war relic."

Just off Utah Beach in Normandy, a

French Army Engineers officer

demonstrated an inert but original

World War Two era "Hafthohlladung"

to this agency in June 2015. |

|

(click for

enlargements)

_small.JPG)

_small.JPG)

_small.JPG)

_small.JPG)

Personal demonstration of the Nazi

Hafthohlladung antii-tank mine. |

|

Due to

local restrictions regarding

weapons, ammunition and ordnance, we

consider our Plexiglas model with

mounted magnets and handling ring

the next best thing to a hollow

magnetic charge. |

|

(click for

enlargements)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg) |

Normal and neodymium magnets were

easily procured online and in local

shops.

|

B. Preliminary study: testing

magnets on actual Zimmerit

- Panther D tank in Breda, 13 NOV

2011

- Panther tank, Technik Museum,

Sinsheim, Germany, 17 AUG 2014

- Schulungsfahrzeug and canon in the

Deutsches Panzer Museum in Munster,

Germany, 20 MAR 2015

|

Panther D tank in Breda, 13 NOV 2011

For a description of this tank see

also

Battle

Relic # 29; Sub File No.: 15-A (15-1). |

|

(click for

enlargements)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg) |

|

Panther tank, Technik Museum,

Sinsheim, Germany, 17 AUG 2014 |

|

(click for

enlargements)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg) |

Schulungsfahrzeug and canon in the

Deutsches Panzer Museum in Munster,

Germany, 20 MAR 2015

To test the Zimmerit in the German

Panzer Museum in Munster, we needed

a special Photography- and

measurement Permit which consisted

of a

pass and a

high-viz vest, allowing us to

even

climb on top of vehicles like the

Königstiger tank. |

|

(click for

enlargements)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg) |

C. Platform: Original World War

Two Nazi right front mudguard of

Königstiger (Tiger II) tank

This agency procured an original

World War Two vintage mudguard of a

Königstiger tank at the 18 MAY 2013

Militracks event in Overloon, the

Netherlands. The German businessman

selling it, claimed to have found it

on a forest floor near Berlin just

shortly before the transaction. It

was not buried in the ground, it

just lay there, he said. This is

consistent with what numerous period

photos of Königstiger tanks which

hardly ever show all 12 mudguards

still attached to the vehicle. It

would only take hitting any roadside

obstacle to lose one or two of these

steel mudguards.

The original mudguard is considered

to be the next best thing to using a

complete World War Two Nazi tank.

|

|

(click for

enlargements)

_small.jpg)

_small.jpg)

_small.jpg)

Right hand side

mudguard, second segment from the

front.

Usually not treated with Zimmerit,

although video evidence proves an

exception.

Click

here for footage of a captured

German Königstiger II tank featuring

mudguards treated with Zimmerit. |

|

D. Zimmerit test in five stages

|

|

1) Sandblasting the mudguard and

coating it with primer paint, 18 MAY

2016 |

|

(click for

enlargements)

|

|

2) Mixing the ingredients and

applying self-made Zimmerit to the

mudguard, 8 JUN 2016 |

|

(click for

enlargements)

|

|

3) Painting the mudguard in Nazi

camouflage scheme,

27 JUL 2016 |

|

(click for

enlargements)

|

|

4) Testing the Zimmerit for its

(non-)magnetic properties, 15 JAN

2017 |

|

The hardened-out product was tested

on this date using various magnets

in a wide variety of magnetic

strength. From household

kitchen or toy magnets, to original

World War Two Nazi "Hafthohlladung"

magnets, to strong modern-day

magnets and finally a Neodymium

magnet. We found that only the

stronger modern magnets are capable

to carry their own weight on the

iron mudguard treated with Zimmerit.

They have the same magnetic forces as felt by

us when we applied them to original Zimmerit in Breda, Sinsheim and

Munster. |

|

(click for

enlargements)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg) |

CONCLUSION:

Not only has this agency been able

to recreate Zimmerit but it has

established that this substance has

certain non-magnetic features

comparable with original Zimmerit

tested with the same magnets.

Given the fact that this agency has

applied Lithopone as an ingredient for 50% of

all Zimmerit to be manufactured and

not to use Lithopone's precursors Sulphide

and Barium Sulphate combined with

the established non-magnetic

features of the product, there now

is a patent application pending for

"Timmerit(Tm)(c)" as we have named

our product.

|

|

.jpg) |

EXHIBITS:

The Zimmerit treated Königstiger II

mudguard now serves as a privacy

protective screen on the balcony of

an apartment in a densely populated

urban area: |

|

(click to enlarge)

|

|

|

|

Back to Battlerelics

|

|

|

|

|

|

| |

| |

| |

| |

|